How to Maintain a Cooling Tower for Optimal Performance?

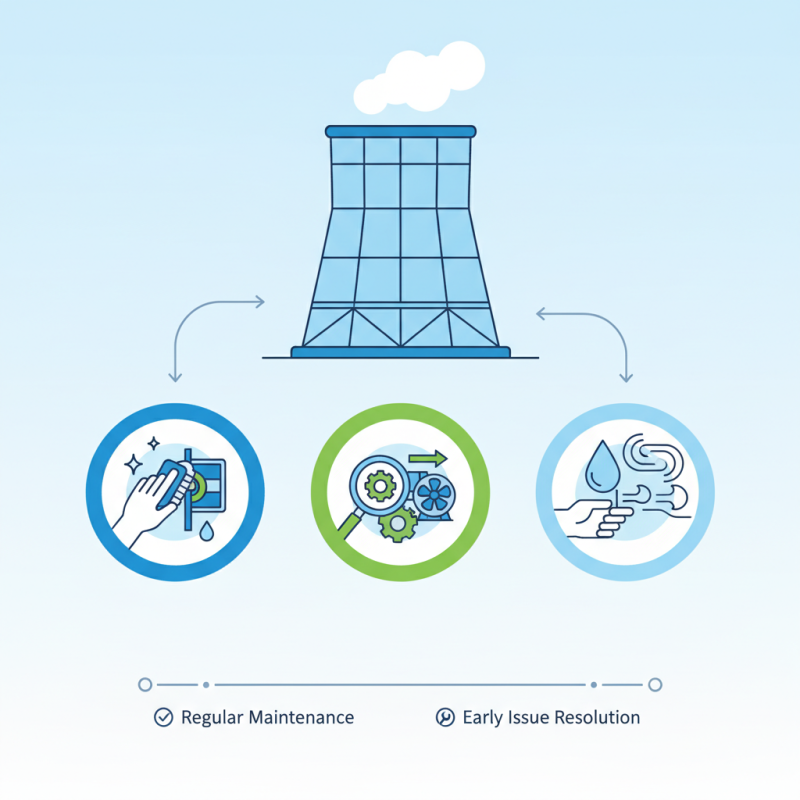

Maintaining a cooling tower is crucial for efficient operation. A cooling tower plays a vital role in many industries. Proper care ensures it performs at peak levels. Over time, wear and tear can affect its efficiency.

Regular maintenance helps identify and resolve issues early. Simple tasks, like cleaning and inspection, can make a big difference. Components like fans and pumps require attention. Neglecting them could lead to costly repairs and downtime.

Understanding how a cooling tower works is essential. It’s not just about keeping it clean. You need to think about water quality and airflow too. Many overlook these factors. A bit of reflection can help you see what you may have missed.

Understanding the Basics of Cooling Tower Operations

Cooling towers are vital for various industrial processes. They dissipate heat from equipment, ensuring optimal performance. Understanding how they operate is crucial. Cooling towers work on a simple principle: water is circulated to absorb heat, then cooled as it evaporates. This process requires careful design and regular maintenance.

To maintain efficiency, regular inspections are necessary. Check for scale buildup, which can hinder performance. Clean the fill media to ensure proper airflow. If the water quality deteriorates, it can lead to microbial growth, causing potential risks. Monitoring water levels and ensuring good water treatment are essential.

Operators often overlook small issues. A minor leak can become a larger problem if ignored. Regularly check for leaks and unusual noises. These can indicate larger mechanical problems. Addressing them early is key to longevity. Inadequate maintenance can lead to costly repairs. Understanding the basics can help prevent these issues and ensure your cooling tower remains effective.

Regular Inspection and Maintenance for Cooling Towers

Regular inspections are crucial for cooling towers. These checks help identify issues early. Keep an eye on water levels and flow rates. Monitor for unusual noises or vibrations. These signs could indicate a problem. Inspect the structure for corrosion or wear. Don't overlook the condition of the fill media. It should remain clean and intact.

Maintenance tasks can easily be forgotten. Cleaning is vital but often neglected. Remove debris from the basin regularly. Check and clean the drift eliminators. Scale buildup is a common issue. Tighten any loose connections. Lubricate moving parts to ensure smooth operation. This helps in prolonging the life of the tower.

Sometimes, maintenance schedules are too rigid. Unexpected breakdowns can happen. Be flexible and adjust as needed. Document all inspections and maintenance activities. This creates a valuable history for future reference. Assess your practices regularly for improvement opportunities. Don't hesitate to seek help if needed. A proactive approach can save time and money.

Cleaning Methods for Cooling Tower Components

Cleaning methods for cooling tower components are essential for optimal performance. Regular maintenance directly impacts efficiency and lifespan. A study from the Cooling Technology Institute reveals that neglected cooling towers can lose up to 30% efficiency. This loss can significantly increase operating costs.

Washing the fill media is crucial. Use a gentle power wash to remove algae and debris. Ensure the water is at a suitable temperature to maximize cleaning without damaging components. Monthly inspections help identify problems early. Consider testing for scale buildup and corrosion, which can affect heat exchange efficiency.

Tips: Regularly monitoring water quality can prevent problems. Use biocides carefully to manage biological growth. Inspect for leaks, as they can lead to severe water loss. Schedule cleanings during off-peak seasons to avoid operational interruptions. Remember, inconsistent maintenance practices may lead to higher energy consumption and increased wear on components. It's necessary to reflect on your maintenance routine for improvements.

Monitoring Water Quality and Chemical Treatments

Maintaining optimal water quality in cooling towers is crucial. Poor water conditions can lead to scaling, corrosion, and biological growth. According to the Cooling Technology Institute, nearly 30% of cooling tower failures arise from water quality issues. Regular monitoring is essential to prevent these problems.

The pH level plays a vital role in water chemistry. Ideally, the pH should be between 7 and 9. If it's too low or too high, problems can escalate quickly. Corrosion can occur when pH is low, while high levels can cause scaling. Regular testing is necessary to keep these levels in check.

Chemical treatments are also critical for maintaining water quality. Biocides help control microbial growth, while scale inhibitors prevent mineral buildup. The dosage of these chemicals requires careful consideration. Over-treatment can lead to harmful residue; under-treatment may not control the problem effectively. It's a balancing act that requires continuous observation and adjustment to ensure cooling tower efficiency.

Troubleshooting and Addressing Common Cooling Tower Issues

Cooling towers are vital for efficient thermal management. However, issues often arise that can hinder their performance. One common problem is scale buildup. This can reduce heat exchange efficiency. Regularly inspect for scale deposits. If found, consider a chemical cleaning process. This ensures that the cooling medium flows freely and maximizes cooling.

Another frequent issue is poor airflow due to debris. Leaves, dirt, and other particles can obstruct fans. Regular cleaning of cooling tower inlets and filters is essential. If clogs persist, airflow can drastically decrease. Monitor fan operation closely. A failing fan motor can lead to inefficient cooling and increased energy usage.

Lastly, vibrations can be an indicator of mechanical problems. It’s key to check the structural integrity of the cooling tower. Loose connections or worn-out components need immediate attention. Ignoring these signs could lead to bigger issues down the line. Always address these common issues to ensure optimal performance.

Article Source:

HEMC (Hospital Equipment Manufacturing Company) was established in the year 1981 and has since been engaged in the export of Medical equipments, Hospital equipments, Orthopaedic Implants & instruments, Laboratory equipments, Scientific & Educational products worldwide. Your support has made us a "Government of India" recognised export house. Our goods have reached all continents from "The Americas" to "Europe" and beyond…